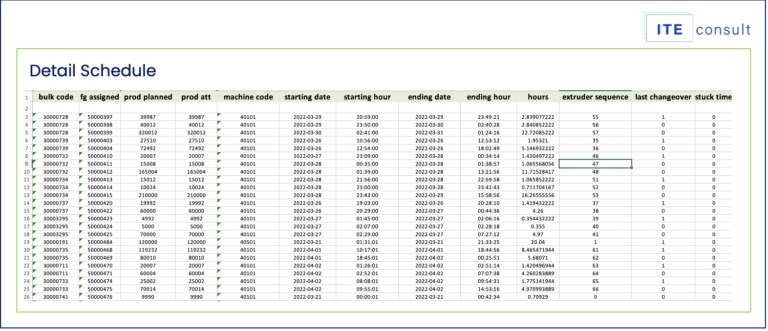

Detail Scheduling

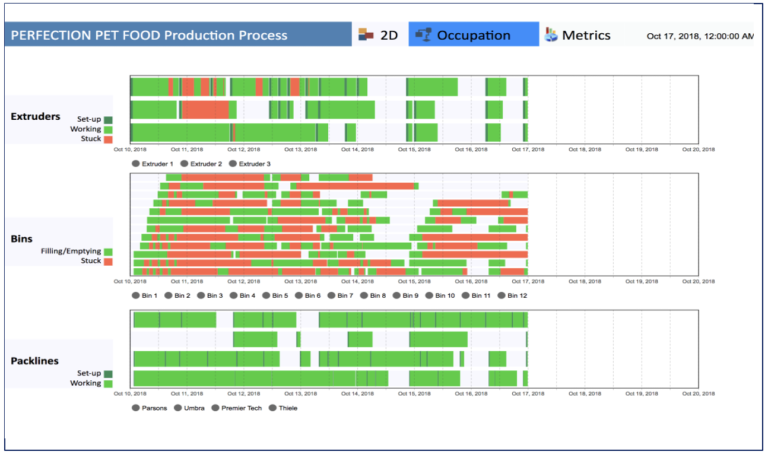

The goal of detail scheduling is to ensure that orders will be executed, that work centers will be available when required in the sequence that the plan defines. Because work centers may be required by different FG at the same time, the sequence of process is critical. Successful scheduling of one operation at a resource may conflict with the dates of the other operations. You need a scheduling of the process evaluating the bottle necks of your resources.

Production is dynamic and restrictions are time related, so it is very hard to try to plan a complex production flow in an excel sheet or in a linear way ( lots of planning tools do so), because probably you won’t be able to capture all the interaction that feeds the best output but with a digital twin this is possible. In a few minutes you will have your monthly or weekly answer!